Steel E-Motive: Autonomous Vehicles That Only Steel Can Make Real

The Steel E-Motive program–commissioned by WorldAutoSteel in partnership with Ricardo plc–has developed the world’s first fully autonomous electric vehicle body structure concept purpose-fit for ride-sharing. This global steel industry initiative showcases the...

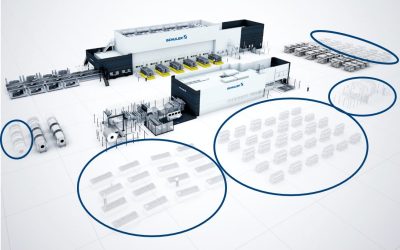

Die-Free Blanking of Class A Quality & Structural Parts

You’ll find this content as part of our page on Laser Blanking, but this month, we want to highlight it in our AHSS Insights blog. We thank Schuler North America for contributing this insightful case study. Production of Class A quality and structural parts...

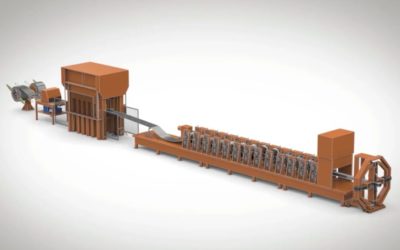

Roll Forming

Roll Forming takes a flat sheet or strip and feeds it longitudinally through a mill containing several successive paired roller dies, each of which incrementally bend the strip into the desired final shape. The incremental approach can minimize strain localization and...

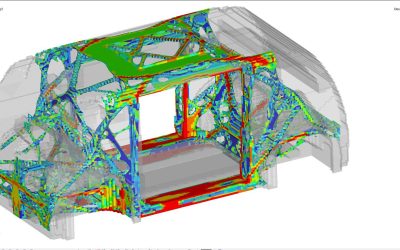

High Strain Rate Testing

Dynamic tensile testing of sheet steels is becoming more important due to the need for more optimized vehicle crashworthiness analysis in the automotive industry. Positive strain rate sensitivity (strength increases with strain rate) as an example, offers a potential...

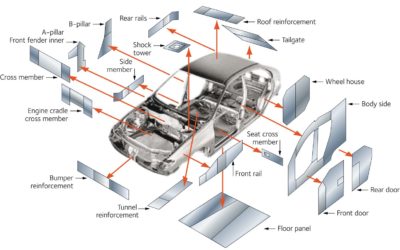

Benefits of Tailored Products in Automotive Body Construction

Key materials characteristics for formed parts include strength, thickness, and corrosion protection. Tailored products provide opportunities to place these attributes where they are most needed for part function, and remove weight that does not contribute to part...

More Reveals of the Steel E-Motive Autonomous Vehicle Demonstration

WorldAutoSteel has a 30-year legacy of steel demonstration all the way back to the Ultra-Light Steel Auto Body (ULSAB), whose engineering report is still being downloaded from our worldautosteel.org site today. The one you may remember best is the FutureSteelVehicle...