Welcome to AHSSInsights.org, the leading online resource for technical information on the forming, joining and metallurgy of Advanced High-Strength Steels for automotive applications.

This site features a searchable database, enabling easy access to critical information on the key benefits of automotive high strength steels and how they can be deployed for manufacture. The content is made publicly available by WorldAutoSteel, the automotive group of the World Steel Association.

AI Expulsion Prediction In Resistance Spot Welding Of Advanced High-Strength Steels

Resistance spot welding (RSW) is the most utilized joining process in car body assembly with exceptionally high demands on quality and reproducibility. Expulsion in RSW leads to ejection of metal...

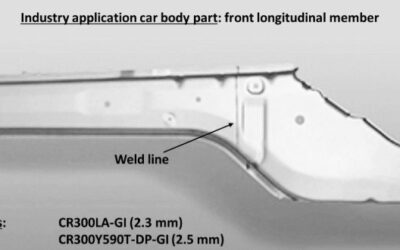

Digitalization In Tailor Welded Blanking: Combining Numerical Simulations To Process Increasing Material Strengths

Efficient energy and resource use in automotive engineering is a major challenge that can only be overcome with innovative solutions. A cost-effective and resource-saving approach is the use of...

WorldAutoSteel Releases Latest AHSS Application Guidelines

Smarter Engineering for Tomorrow’s Vehicles In the fast-evolving world of automotive engineering, the ability to innovate safely and efficiently is paramount. Advanced High-Strength Steels (AHSS)...

Mild Steels to Advanced Steels: The Phases Make The Difference

Steel’s performance starts at the atomic scale, where tiny changes in how iron and carbon atoms arrange themselves create dramatically different properties. This article explores how those atomic...

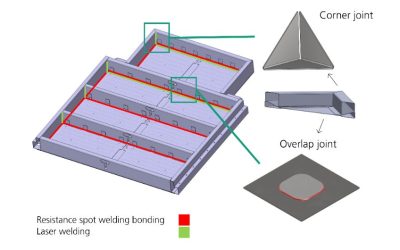

Life Cycle Assessment of Welding Methods for EV Battery Enclosures | Environmental Impact Comparison

With the rise of electric vehicles, evaluating the environmental impact of each manufacturing process is essential. This article presents an EV battery enclosure welding LCA to compare the...

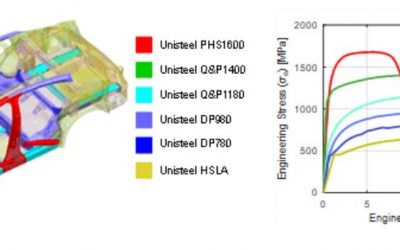

Press Hardening Steel Grades: Unlocking Strength Through Innovation

You’ll find most of this content as part of our page on Press Hardening Steel Grades, but this month, we want to highlight it in our AHSS Insights blog. Thanks to Eren Billur, Ph.D., President,...